CFD Modeling

Optimizing Data Center Design through CDF Modeling

Traditionally, when designing a data center fit-out, the first approach is to determine the maximum cooling capacity for the space. Server racks and cooling equipment are then positioned according to the manufacturers’ spacing recommendations. Laying out the equipment based on these recommendations means relying on assumptions about airflow and heat distribution, which may be incorrect and lead to higher energy use and increased operating costs. Now, EKFox is capable of using computational fluid dynamic (CFD) anlalysis to simulate airflow and temperature patters, clarifying the unknowns and removing the guesswork for the best results possible. This saves our clients money as their data centers operate more efficiently.

EKFox was tasked to design, model, and analyze a 4,000 square-foot data center that supports an energy consumption (IT load) of approximately 810 kilowatts. The new electrical and mechanical equipment were required to be consistent with the existing building equipment. The baseline model and layout for the data center were initially drawn using AutoCAD, and we used 6Sigma Room from Future Facilities to convert the 2D AutoCAD model into a 3D virtual facility model for our CFD analysis.

CFD Analysis Results

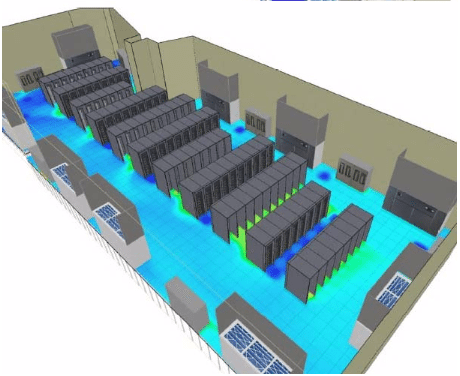

The results of our CFD analysis for this data center showed potential areas of “hot-spots”, where a server rack was receiving insufficient flow of cool air. We were also able to locate areas of cooling inefficiency, including short cycling and bypass air, where the cool discharge air from the cooling unit is cycled back and causes the unit to end its cooling cycle prematurely. We were then able to calculate the power utilization effectiveness (PUE), which shows the ratio of total facility energy usage to the energy usage from the server racks only. This highlights the efficiency of the data center’s cooling system in concrete terms.

Using CFD Analysis Information to Add Value

Using the information from our CFD analysis, we were able to modify our virtual facility model to reduce the predicted hot-spot and short-cycling areas. This was accomplished by rearranging the rack layout into a hot aisle and cold isle and by adding hot aisle containment curtains. In all, these modifications removed these hot-spots and short-cycle areas, which in turn reduced the PUE value, showing an increase in cooling efficiency. Without our CFD analysis, the problems would not have been identified until after the data center was built-out. Mitigating these problems before build-out saved both time and money, adding to the value EKFox delivered to the client with this project.